The Wonders of Trenchless Sewer Repair

- by

Trenchless Sewer Repair and its Brief History

Trenchless sewer repair has come a long way. The advent of trenchless technology began in 1970 when an Englishman named Eric Wood developed the first cured-in-place piping. When Wood, an agricultural engineer at the time, needed to repair a broken air duct above his mushroom bed, he knew just what tool would be necessary.

The repair work on this pipe was more complicated than it seemed, and Wood had to develop an innovative technique to complete the necessary repairs.

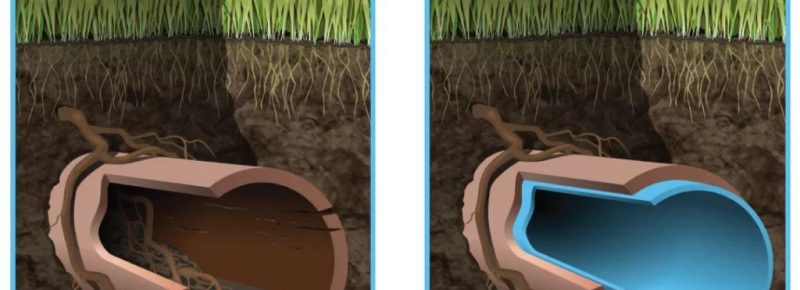

He came up with a solution called CIPP, or cured-in-place piping, which is now commonly used for trenchless pipe repair. It involves installing a saturated felt-like material with epoxy or resin, then curing it into place in the affected pipe.

This process removes joints from the piping since the felt material is measured to the entire pipe length. In addition it is commonly used to protect sewer lines from root intrusion or pipe shifting.

In the mid-1970s, some contractors sought an easier way to break up old underground pipes to replace them. The use of new technology was becoming accessible at that time. Consequently, it seemed like a perfect solution for these aging infrastructure components.

The engineer who came up with this process was tired of spending his days replacing old pipes. So he designed something that would make getting rid of them more manageable, safer, and more cost-effective; the now-famous pipe bursting technique.

Pipe bursting is a quick and straightforward fix for your pipe-related problems. Furthermore, this is done by breaking up the existing pipe then installing another one in its place.

The Many Innovations of Trenchless Sewer Repair

In the late 1970s, the development of micro tunneling in Japan was one way the country could overcome certain soil conditions. This technique is becoming more common in environmentally sensitive areas.

The innovations in pipe repair came along with the expiration of patents, including directional boring and point-repair. These methods allow faster repairs on smaller sections without digging up the entire street.

Trenchless sewer repair has indeed come a long way and continues to be an efficient and less invasive technology.

How Does Trenchless Sewer Repair Work?

1. Cleaning the Lines

The first step in lining pipes with epoxy or polymer resins is to prepare any surfaces that will become coated. In addition, various techniques remove scale, buildup, and other impurities from the pipes. The different cleaning techniques available to remove scale and rust involve water jets or a dry-mechanical method. These include spinning chains that can break up calcium carbonate deposits in your pipes with relative ease.

2. Preparing the Lining

The lining process begins when the pipe has been prepared and dried sufficiently. Next, our professionals measure and cut the structural felt liner to match the length of your pipes. Then, the resin is mixed and added to the liner. The liner is then “wet-out” or pressed to ensure complete saturation with the resin. The liner is either shot into place via an air-compressed drum or pulled utilizing a second access point such as a cleanout. Once the liner has been installed, air pressure will inflate it to its final shape. Once the liner is correctly applied, it’s left to cure. The process can be expedited with steam or specialized UV equipment for an even faster turnaround time.

3. Send in the Robots

Once the resin has hardened, the inflatable bladder is removed from the pipe, and robotic branch reinstatements can begin. This is the final step of trenchless sewer repair. Now that all your branch lines are open, the professional can reestablish the drain fixture.

Why Choose Jetters ‘N’ Drains

Our focus is to cater to our client demands by providing high quality, reliability, durability, and value standards.

We use the latest state-of-the-art equipment to give our clients peace of mind knowing the job is done right the first time.

Call us for a free consultation

(714) 640-6534

Related Links:

- Sewer Line Repair & Replacement

- 24/7 Professional Pipe Services

- Video on Trenchless Sewer Pipe Repair, Replacement and Relining – Sewer Surgeons